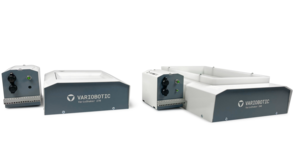

VarioShaker Component Separator

Through many years of experience in the field of special machine construction, Variobotic GmbH can transfer the know-how from industry to robotics.

They support small and medium-sized businesses from the industrial sector by providing low-cost automation solutions. As an official DOBOT sales partner, they market selected DOBOT robotics products for industry and education and enable flexible part feeding with their own development, the component separator.

Through a broad partner network, Variobotic GmbH works in close cooperation with other robot manufacturers and vision systems and therefore offer the possibility to realize a complete automation solution. In this way, individual solutions can be implemented together.

Product Description:

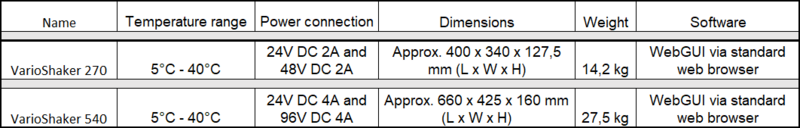

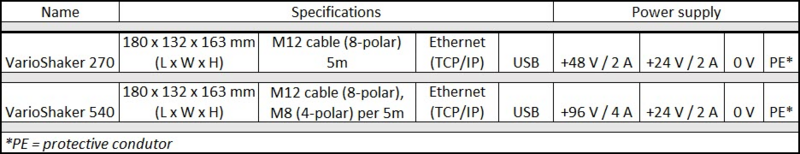

The VarioShaker 270 and the VarioShaker 540 component separator are more than just a simple component separator. Not only can it be flexibly adapted to different components, it can also be used to separate them.

A high separation rate is achieved through targeted movement of the bulk material. Collecting the parts and shattering them again is no problem either.

There is also the option of emptying the vibrating platforms. The main applications are in the areas of pick and place and flexible feeding.

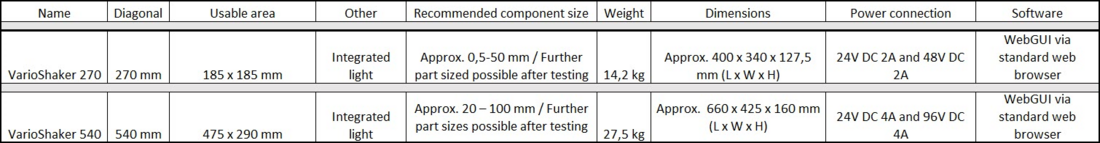

Compared to conventional systems, the VarioShaker 540 is easy to set up and configure as well as robust and uncomplicated in operation. Components with different shapes can be separated by controlled movements.

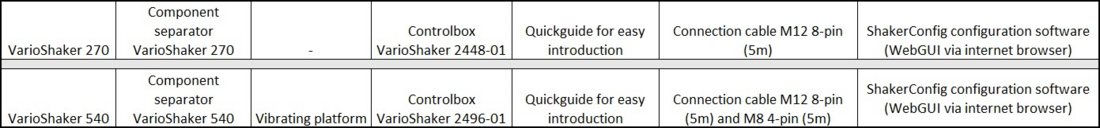

In addition to a web-based configuration for easy operation, the VarioShaker 540 has an I/O interface and can therefore be adapted to almost any robot. When sorting bulk material in the correct shape and position, the VarioShaker acts as a link between a vision system and an industrial robot.

Further Product Features:

o Adaptable to almost any robot through I/O Interface (FANUC, fruitcore robotics, Yaskawa, Universal Robots, Yuanda Robotics, Epson und Techman)

o Web interface software: easy to setup, configurate and end- device independent

o The software can be operated without specialist knowledge and was designed to meet the needs of the user.

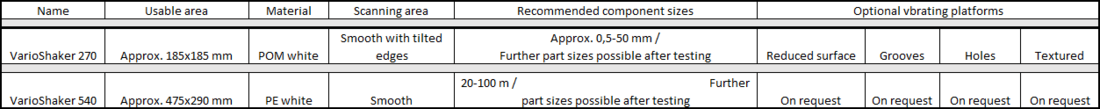

o Different kind of surfaces of the vibrating platform allow the VarioShaker 270 to be adjusted to the processed component.

o Part recognition independent of extraneous light

o Quick-change of the vibrating plates

o Easy commissioning thanks to intuitive software

o Fast production changes

o Thanks to the TCP interface to the vision system, the VarioShaker can be freely controlled directly, without any software.