Servo technology

Servo technology increase the effeciency and quality of the man controlled mechanical works. Servo systems does precise handling and positioning tasks.

Those industrial applications are becoming more common, which needs some axes controlled synchronization.

Kollmorgen well known name as worldwide in electrical and mechanical servo system parts like as servo drives, servo motors, gearboxes, linear moving element.

The market needs those drivers which are dynamically developed and has low price, reliable delivery, high quality.

Kollmorgen which is a famous brand name match these expectations. All components for your servo system from one company, these elements are may AC synchronous servo motors, servo drives, gearboxes or additional accessories like cables or extension card.

AKD2G Servo Drive

Flexible

- One and two axis variants available

- Modular design allows the user to specify only the features needed

- Plug&Play Compatibility With All Kollmorgen Motors

- Optimized For Single Cable (SFD3 & HIPERFACE DSL)

- Optional Feedback Port for

- EnDAT 2.2

- BiSS

- Resolver

- A-QUAD-B Encoder

- Encoder emulation

- Dual-loop

- Multiple bus choices for system optimization, including EtherCAT®, and CANopen®

- SIL-qualified

- Dual-channel STO for each axis

- Industry-leading power density for greater flexibility in mounting

- Fits into a 10” deep control panel

- Removable Memory

- I/O

- Dual-Channel STO

- 16 I/O included

- Optional I/O expansion to 28 I/O

Easy to Use

- Plug-and-play compatibility with Kollmorgen controls and motors

- WorkBench GUI for full funkcionality

- Hybrid Motor-Power connector is optimized for single-cable motors:

- No adaptors, no D-subs, no splitters

- Cage-clamp spring terminal connectors on I/O allow for fast and easy installation

- Optically-isolated I/O reduces noise, and eliminates need for additional hardware

Fast

- Servo on a Chip™ includes Dual-Core ARM™A9, 800 MHz + 1.5M additional FPGA gates

- Accommodates changing load conditions immediately:

- Current loop: 1.28us, nearly 50x the speed of our nearest competitors

- Velocity loop: 62.5us

- Position loop: 125us

- AI-based auto-tuning with a click of a button gets you started quickly

- Wizard-based tuning uses advanced Bode Plot tool to help you efficiently manual-tune when desired

- Fast data acquisition with TCP/IP Ethernet service channel

AKD® Servo Drives

The Kollmorgen AKD® Series includes a complete range of Ethernet-based servo drives that are fast, feature-rich, flexible and easy to integrate into any application.

Features:

- Can be embedded with our innovative Kollmorgen Automation Suite™ for high-performance single- and multi-axis systems

- Kollmorgen WorkBench graphical user interface for easy set-up and programming

- Plug-and-play compatibility with Kollmorgen motors

- Digital signal processor control supports reliable, repeatable steps

- Optically isolated I/O with screw terminal I/O connectors

- Highest bandwidth torque-and-velocity loops. Fastest digital current loop in the market.

- Full-frequency, wizard-based autotuning

- Fast data acquisition with PC-compatible TCP/IP Ethernet service channel

- Real-time performance feedback

- Feedback Devices: Smart Feedback Devices (SFD), EnDat2.2, 01, BiSS, Analog Sine/Cos encoder, incremental encoder, HIPERFACE®, and resolver

- Multiple bus choices for system optimization, including EtherCAT®, SynqNet™, Modbus/TCP, CANopen®, EtherNet/IP and PROFINET.

- SIL-qualified, over-voltage, current, and temperature detection provided for added dependability

- Option cards available to increase I/O, add NVRAM and boost processing power

>>AKD® Series Servo Drives CAD Drawings

>>AKD® Series Servo Drives Manuals

AKD® BASIC Programmable Drives

With the addition of an on-drive BASIC-programmable drive/controller, the AKD® Series achieves a new milestone for versatility and ease of use.

AKD BASIC allows single-axis applications to be handled in the same package sizes as the standard AKD drive, without the need for a separate controller.

Features:

- Machine control and high-performance motion controller built in to the drive for 1.5-axis control (1 real, 1 virtual axis)

- Standard version:

- 7 configurable digital inputs (+1 dedicated to enable)

- 2 configurable digital outputs (+1 fault relay)

- 1 analog input and 1 analog output

- Service port for commissioning, programming and Modbus TCP/IP

- Expanded I/O version:

- 20 digital inputs (1 dedicated to enable)

- 12 digital outputs (1 dedicated fault relay)

- 2 analog inputs and 2 analog outputs

- SD memory card for program and parameter storage

- Service port for commissioning, programming and Modbus TCP/IP

- Available in the same power and voltage levels as our AKD® Series

- BASIC programming language, including the ability to use conditional statements

- Programming interface is a standard feature of AKD WorkBench, and includes ease-of-use features such as automatic syntax highlighting, auto-complete, auto-format and code templates

- Source code lockout feature with password protection

>>AKD® BASIC Programmable Drives CAD Drawings

>>AKD® BASIC Programmable Drives Manulas

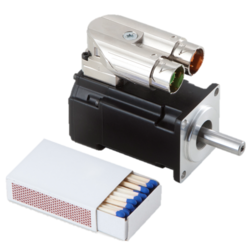

AKM®2G Series Servo Motor

Features

- Greater than 20% average increase in torque density (torque/volume) for highest torque or smallest footprint sizing

- Six design sizes with performance levels between 0.3 and 10 kW

- Continuous torques from .0651 Nm to 75.2 Nm

- Frame (mounting flange square) and stack (motor length) combinations with overlapping ratings for optimal motor package sizing

- Standard winding choices for 120VAC to 480 VAC operation with various speed/torque performance curves

- Feedback Options to match application requirements and drive selection

- SFD3

- Hiperface DSL

- ENDAT 2.2

- Resolver

- Others future availability/by request

- Connector Options (as appropriate for feedback type and motor size)

- SpeedTec * (standard for single or dual cable designs)

- Y-Tec (dual connector with single insertion at motor for size 2 motors)

- System Cable Options for use with Kollmorgen AKD Servo Drives and the AKD2G Servo Drives

- Single Cable SFD3/Hiperface DSL/ENDAT 2.2

- Two-Cable Variant For Resolver including ytec connector motors

- Standard IP65 rating, optional ratings available

- International Standard Mount with choice of smooth shaft or closed keyway

- Others future availability/by request

- Mechanical Holding Brake Option

- Future availability for permanent magnet brake option

- Thermal Sensor Options for maximum motor protection and servo drive compatibility

- Low Friction Shaft Seal Options for both wet and dry running applications

* SpeedTec is a trademark of TE Connectivity Ltd

>>AKM2G Interactive Selection Guide

>>AKM2G CAD Drawings

>>AKM & AKM2G Performance Curve Generator

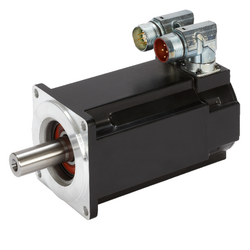

AC Synchronous Servo Motors - AKM™ Series

Features

- 8 frame sizes, 28 frame/stack combinations

- Speeds up to 8,000 RPM

- 75 VDC; 120, 240, 480 VAC windings

- A wide variety of feedback devices, mountings and seals

- Direct mate to most Kollmorgen servo drives

- Windings are rated at 100°C rise over a 40°C ambient while using 155°C (class F) insulation materials

- cURus, CE Compliant, UL Recognition

Options

- Feedback devices: resolver, SFD, incremental and sine encoders

- Seals for improved environmental protection

- Shaft ends closed or open keyway, flat, smooth

- Dual or single Intercontec connectors, straight or rotatable

- 24 VDC fail-safe brakes

- IP67 washdown versions with food-grade greases and finishes

Benefits

- Unprecedented choice and flexibility from a wide range of standard products and co-engineered modifications for an exact fit to your design requirements

- Best-in-class performance, with industry-leading power density

- Exceptionally low cogging and low harmonic distortion to ensure smooth performance

- Easy to commission and use, with plug-and-play motor recognition and full-frequency autotuning on AKD™ Series servo drives

>>AC Synchronous Servo Motors – AKM™ Series CAD Drawings

>>AC Synchronous Servo Motors – AKM™ Series Manuals

AKM DC Servo Motor Low Voltage

Low voltage. High performance.

24 and 48 volts: KOLLMORGEN expands its AKM servomotor series.

Energy efficiency, durability, power density, overload capability:

KOLLMORGEN has now transferred these four benefits of permanent-excited servo motors to the extra low voltage world.

Features

- Torque range up to 1,25 Nm (continuous) and 4,1 Nm (peak)

- 2 voltage ranges: 24 V DC and 48 V DC

- 3 sizes with 40, 58 and 70 mm flanges

- Rated speed range up to 2500 rpm

Advantages

- All the benefits of permanent-excited servo drives in a low voltage environment

- Replaces existing drives

- Power range up to 300 W (48 V)

- Full flexibility of the AKM range in terms of feedback systems, connectors and flange/shaft combinations

>>AKM DC Servo Motor Low Voltage Manuals

Features of Servo drives:

- 230-480 V AC, 50 Hz or 20-90 V DC power supply range

- 1,5-70 A current range

- directly controlled by Danaher Motion pc software /Drive, DriveGUI/

- serius communication profiles: Step/Dir, ProfiBus, CANOpen, digital and/or analog analóg I/O, Sercos

- fully programable by RS232 interface

- included position controlling and different movement curves saved in drive

- digitally parametric speed and rpm

- integrated oscilloscope software for settings evaluation

- parameters and settings saving and restoring option by MMC memory card

- CE and UL certification

Features of Servo Motors:

- Three or one phase brushless servo motors

- Two poles, 1024/turn resolution standard resolver feedback, single or multiturn absolute encoder feedback also available

- Long lifetime

- 230-480 V AC, 50 Hz or 75 V DC power supply range

- 1200-8000 rpm rev range

- 0,1-115 Nm torque range

- IEC standard parameters

- CE certificate

Features of Servo Motor’s Options:

- Brake

- Shaft with standard keyway

- Shaft sealings

- Different types of feedbacks and connections

- High resolution singleturn and multiturn high precision absolute

- Smart feedback device

- Direct cooling