Lubrication Systems and Solutions

Dropsa is one of the world's major producers of centralized lubrication system and components for machinery, system, plants. With its wide experience and applications in various type of industries, Dropsa is your competent partner for lubrication solutions. Dropsa has a world-wide reputation for superior quality, performance and value of its items and for dedication to exacting quality standards in design, engineering and manufacturing. We offer a complete line of standard and custom distribution feeders, pumps, controls, auxiliary equipment and fixtures to build and support almost every kind of lubrication system.

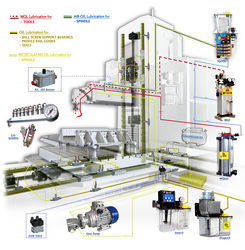

Main lubrication system solutions

- Total loss lubrications;Used in a large range of applications, total loss oil lubrication involves creating a thin oil-film between moving parts which is renewed at regular intervals by an automated lubrication system.

- Recycrulating oil lubrication; Oil re-circulation involves a continuous oil flow to the lubrication point. The oil is collected by drains to a supply tank and re-circulated back to the point. The pump station is equipped with cooling, heating and instrumentation to maintain the lubricant at optimal temperature. In an oil re-circulation system the bearing housing is kept full of oil whilst the fast change-over of lubricant removes heat allowing the user increases in speed and performance. The key to a good lubrication system is the careful monitoring of the lubricant supply - Dropsa has one of the most advanced systems available to achieve this.

- Air/Oil lubricaiton; Rapidly expanding Air/Oil lubrication technique is replacing both Mist Systems and Oil re-circulation systems. Several applications can benefit from Air/Oil System and from the substantial cost savings that can be achieved using it. Dropsa offers many articulated solutions to Air/Oil Lubrication - the VIP4 Family of products is the latest addiction to this range.

- Grease lubrication;Grease lubrication has a wide field of application ranging from small machines such as woodworking machinery to large heavy industry such as steel plants or paper mills. The large section of pump packages together with many custom design options allows any grease lubrication to be developed reliably and cost-effectively. The most popular systems used for grease lubrication are Dual Line and Progressive Divider Systems.

- Minimal Quantity Lubrication (MQL) and Near Dry Machining; The aim of near dry machining is to replace traditional coolant and pure oil flood systems in a machining environment with an accurately controlled compressed air stream that carries minimal quantities of oil lubrication in an "aerosol" format to the cutting surface. This ensures lubrication of the cutting surface and allows for high performance machining. Lubricating Aerosol is transported to the cutting surface in two ways: 1/ With External Lubrication: oil is transported via a nozzle to the cutting surface. Dropsa has a complete product line from simple, easy to install products such as the Grip and Vip4Tools series for External lubrication. 2/With Internal or "through-the-tool" lubrication: oil is transported through internal lubrication holes in the cutting tools. The MKD-Dual product leads the way with patented technology that generates specifically profiled micron-sized oil aerosol particles that can be injected through existing spindles and tool-holders to the leading edge of the cutting tool.

Complete range of components

- Pumps; Dropsa has developed a wide range of standard electric, pneumatic and hydraulic pump packages suitable for oil loss systems. A custom service design is available to tailor pump packages for specific customer applications. The operation will be: electric, manual, pneumatic, hyraulic, gear and cam operated pumps. Soma types of range are Picolla, Smile, Locopump, Cannonpump and more.

- Dividers; Dropsa provides an extensive line of equipment for grease lubrication and system monitoring, as Progressive and Dual Line series. The modular system consists of two main components: the base and the metering elements.

- Injectors & Restrictors; flow regulators for oil circulating installations, spiral and cylindarical meter units, 33V injector series – positive displacemenet injectors, DL32 injetor series – grease injectors, DL1 injectors.

- Manifolds; 01 manifolds, 33V manifolds, W type manifolds, system 06 bilateral manifolds plain, ones and bilateral light alloy manifolds for valves Accumo and Accumino.

- Fittings; compression, push-in fittings, grease nipples, anchor blocks, snap-on, pipe clips.

- Tubing & Tools; steel-, cooper-, cooper plated tubes, nylon and hoses.

- Controllers; These are mainly used to monitor lubricant flow. Depending on the product many other parameters can be electronically stored. Vip5 controller - a feature packed compact Advanced Lubrication Controller for small and medium lubrication systems, Fact 2000 flow rate meter - for medium and large lubrication systems.

- Sensors & Monitoring Devices; These items are pressure- or flow controls, spool sensor and level swithes or sensors.

- Valves; pressure vent valves, by-pass valves, non return valves, electric solenoid valves, hydraulic valves and pneumatic valves.

- Filters; high pressure filters, magnom - magnetic submicron filters, fitting with filter for feeder line, filter with steel body.

- Reservoirs; pressurized grease reservoirs suitable, drain reservoirs.

- Accessories; ringing alarms, oil cans, sprayer, funnels, indicator lamps, grease guns, grease and oil dispensers, caps, brushes.