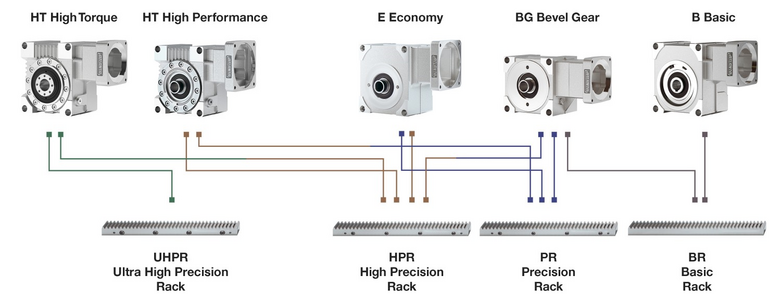

Precision racks

The new quality classes of ATLANTA racks with hardened & grounded teeth, reduce frictional losses and create high-efficiency rack & pinion drives at a level never achieved before.

UHPR – Ultra High Precision Rack:

- Quality 4 and 5 , 12 and 30 μm/m total pitch error

- Modules 2-12, max lengh up to 1 and 2m

- Quality 6 and 7, 48 and 60 μm/m total pitch error

- Modules 2-12, max lengh up to 1 and 2m

- Quality 8, 60 and 100 μm/m total pitch error

- Modules 2-5, max lengh up to 1 and 2m

- Quality 9 and 10, 150 and 200 μm/m total pitch error

- Modules 1,5 - 12, max lengh up to 1 and 2m

- Quality 5-8, tolerance <5 - 25

- Modules 2-12

Applications:

- High precision machine tools with electrical preload

- Machine tools, lifting axes, multiple pinion contact

- Wood, plastic, composite, aluminium working machines

- Machine tools, integratable racks, water cutting machines, tube bending systems, plasma cutting machines

- Wood working machines, linear axes with high requirement for a smooth running

- Portals, handling linear axes, welding robots

- Linear axes with low load feed units for adjustment

Assembly of ATLANTA racks to the correct pitch

Mounting Pinion for Key Connection

Downloads